模型手办3D打印机首选,容易操作且打印表现不俗。

The Progress of Jewelry 3D Printing

China’s jewelry industry has been facing unprecedented challenges over the past few years, due to the emergence of E-commerce live streaming, new retail, new media, as well as an increasing number of novel jewelry brands and manufacturers. After nearly two decades of high growth, traditional jewelry companies are now going through a difficult time, and are plunged into the dilemma of overcapacity, homogenization of brands, and intense price wars.

In this context, a bottom-up reform is brewing in China’s jewelry industry. As Industry 4.0 gains momentum, it is essential to upgrading the jewelry manufacturing process and making it more efficient, more intelligent, more advanced, and faster. Low-cost and flexible production has become the common pursuit in the upstream jewelry supply chain.

Meanwhile, diversification of consumption has driven consumers to seek fashion brands and also bespoke products. Because of the unique portability and wearability, jewelry not only embodies personal style, but also accounts for an important part of the custom market.

3D printing has become a trend in the critical period of transformation and upgrading of the jewelry industry, and has evolved into an innovative approach to the transformation of the jewelry industry.

3D Printing Shapes up the Future of the Jewelry Industry

3D printing was introduced into the jewelry industry more than 10 years ago. Back then it was known as rapid prototyping technology and was used for model making. In recent years, 3D printing has grown by leaps and bounds, and has drawn people’s attention to 3D printed jewelry.

Now 3D printing technology can satisfy consumers’ needs for diverse jewelry styles by providing efficient, convenient bespoke choices. In other words, consumers can participate in jewelry design, to make sure that their individual needs are fully realized. Besides, a lot of jewelry companies have been expanding their creativity through 3D printing. Compared with traditional jewelry manufacturing process, 3D printing has the following advantages:

☆Remarkable Improvement of Efficiency

The traditional jewelry manufacturing process consists of many complex procedures including silver model making, rubber mold pressing, rubber mold cutting, wax injection, and mold repair. It is also costly in terms of equipment, venue, materials, labor, and time. 3D printing has largely replaced manual work, reduced many procedures, and shortened working hours markedly. According to reports, compared with the hand-made process, a 3D printer can make the same piece of jewelry more than ten times faster.

At present, 3D printing technology is mainly used to replace the wax molding step. A highly skilled wax engraver is essential to a piece of handmade jewelry that mirrors the design. On the contrary, a 3D printer can print out multiple wax models at the same time, which are exact copies of the design model. Thus, it can save a lot of time spent on manual model making, and avoid many errors and defects as well as unnecessary waste in the process. In the meantime, by ensuring high quality and precision of the models, it helps lower down production costs and increase production efficiency markedly.

After the 3D printer prints out the wax model, the lost wax casting process follows to create the silver mold, and then a series of processes are performed such as rubber mold pressing. Today, 3D printers can completely replace manual model making, to facilitate mass production, and large-scale, standardized production in factories.

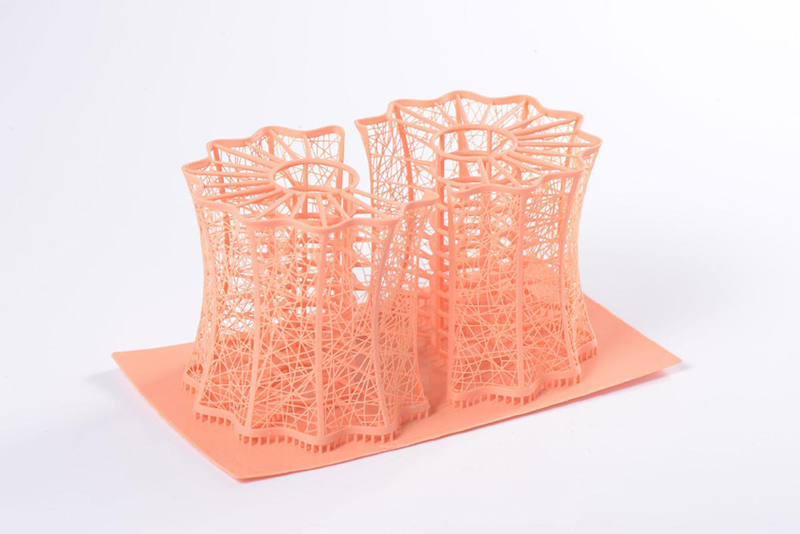

3D Printing of Intricate Structures

☆Encouraging the Cultivation of Design Thinking Mindset

In the traditional manufacturing process, designers have to put manufacturability first when working on jewelry design. Otherwise the design would end in fanciful ideas.

However, even though designers have given top priority to manufacturability in the design stage, sometimes products still cannot be manufactured through traditional handcraft. It has occurred rather frequently. Under the circumstances, mass production is out of the question. Unlike the traditional manufacturing process, 3D printing technology can be used to bring to life novel shapes, and imaginative ideas and designs.

That is one of the key features of jewelry 3D printing technology. It allows designers to give free rein to their creativity, to satisfy the personalized needs of young people for jewelry design, and to mass produce their designs.

☆Complementary with Handicraft and Design

As 3D printed jewelry is often compared with traditional handmade jewelry, some people are concerned that 3D printed jewelry would eliminate the typical characteristics of traditional jewelry. Actually, though 3D printers and other cutting-edge technologies have been introduced into the jewelry manufacturing process, human perception still plays a very important role. Throughout printing, production and the subsequent processing, manual work remains an integral part. That is to say, human perception and manual work are still key factors to the creation of stunning jewelry.

In the jewelry industry, technology is still considered a useful tool, which is complementary with the traditional jewelry making and design. Traditional jewelry design is a process of artistic creation, during which novel ideas and unexpected results may come out. 3D printing, however, produces exactly what is designed, unless the printer breaks.